csmg

New Member

Posts: 34

|

Post by csmg on Nov 25, 2018 11:48:54 GMT -5

Good morning, I have noticed on my pro8 that when I use the touch off puck for the depth, I am never the depth that I select in vcarv pro. I am typically having to go about 4-5 thousands greater to ensure I cut through the part of get the depth I need. I am tired of guessing.

I texted Austin and he suggested to check the puck thickness in the richauto controller. However, I have not been able to find where to check that setting. My puck measures .981 as an average of 4 measurements.

Does anyone have experience with the Richauto controller on where to verify the setting?

Thanks

|

|

|

|

Post by gerry on Nov 25, 2018 12:57:48 GMT -5

I attached part of the manual. You want to look at the C.A.D. Thickness. This is where you set the puck thickness. You may also want to set TOOLSET SPEED. This is how fast the Z-Axis goes down when zeroing on the puck. I slowed mine way down to stop the divots in the puck and get a more accurate setting. AXIOM CAD Thickness.doc (263.5 KB) |

|

grg

Junior Member

Posts: 140

|

Post by grg on Nov 25, 2018 19:59:44 GMT -5

I attached part of the manual. You want to look at the C.A.D. Thickness. This is where you set the puck thickness. You may also want to set TOOLSET SPEED. This is how fast the Z-Axis goes down when zeroing on the puck. I slowed mine way down to stop the divots in the puck and get a more accurate setting. Great Tip! Thank you. I had a spring loaded puck on my to-buy or to-make list because of that but slowing that down worked like a champ. Thanks! |

|

|

|

Post by savannahdan on Nov 26, 2018 10:09:31 GMT -5

A big thank you from me as well. I knew how to measure the thickness of the puck but didn't look at slowing the TOOLSET SPEED. I've been using the manual process by lowering to a thin sheet of paper.

|

|

|

|

Post by gerry on Nov 26, 2018 10:46:06 GMT -5

I usually zoom the Z down normally to about puck height, slide the puck under the bit, and zero the bit. That way it doesn't really take much extra time. A few extra seconds is better than breaking bits. It will now zero 'micro bits' with no problem.

|

|

|

|

Post by JohnnyBeWood on Nov 27, 2018 22:31:10 GMT -5

I attached part of the manual. You want to look at the C.A.D. Thickness. This is where you set the puck thickness. You may also want to set TOOLSET SPEED. This is how fast the Z-Axis goes down when zeroing on the puck. I slowed mine way down to stop the divots in the puck and get a more accurate setting. Great Tip! Thank you. I had a spring loaded puck on my to-buy or to-make list because of that but slowing that down worked like a champ. Thanks! Where have you seen alternative pucks? I wanted one that has a telephone style cord that springs back. |

|

|

|

Post by gerry on Nov 27, 2018 23:47:07 GMT -5

You could attach any wire you want. It is only a single wire. One end to the phone jack, the other to the puck.

|

|

grg

Junior Member

Posts: 140

|

Post by grg on Nov 28, 2018 8:04:30 GMT -5

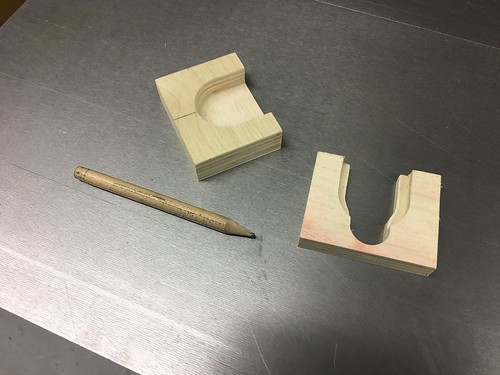

Great Tip! Thank you. I had a spring loaded puck on my to-buy or to-make list because of that but slowing that down worked like a champ. Thanks! Where have you seen alternative pucks? I wanted one that has a telephone style cord that springs back. Any touch off puck will do. As gerry said, it's just a simple one wire circuit that closes the loop and you can use something as simple as a plate of aluminum with a wire on it like one of the other brands do. I bought my Axiom used and the puck was missing so I bought an $8 puck on ebay. I wound the wire around a rod and heated it with a heat gun to soften and reset the wire insulation which gave it some coil (it works but it's not ideal). I then made a little holder that I double sided sticky-taped to the bridge upright. Once I fine tuned that puck height setting in the controller, it's worked like a champ except that the bit keeps marking up the soft aluminum of the puck. That's when I decided I would come up with a spring loaded puck that would spring back to the zero setting but absorb just a little bit of motion (or buy one - they are available) - however, reducing the speed of that z search works like a champ.   |

|

|

|

Post by JohnnyBeWood on Nov 28, 2018 10:05:12 GMT -5

Thanks for the tips!

|

|

|

|

Post by buildswithbrian on Dec 8, 2018 7:06:45 GMT -5

thanks for the tip on the downspeed

I will give it a try.... been having the same problem with the puck,

I've also been thinking of machining my puck down to a more precise and even measurement

(in millimeters) because it doesn't measure exactly 1" either, and changing the thickness in the settings.

thanks for posting!

|

|

|

|

Post by southernginger on Jan 5, 2019 7:47:51 GMT -5

I also have a video on this if it helps anyone.

|

|